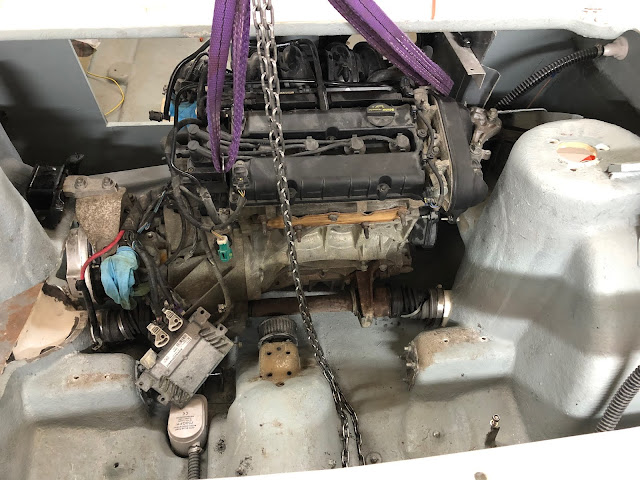

An interesting week. A simple job of getting the engine mounted in the car. It didn't work out at all as expected!

Before lifting in the engine I mounted the bracket that holds the drive from the gearbox to the water jet.

Thats simple enough so its just a simple lift into the car..

The first problem is there is absolutely no way of getting it in with the bracket. So that has to come off. Take 2. Tried again with out the bracket. No luck, but I did manage to snap off the top of the dipstick!

Oh Dear - never mind. It was apparent fromand subsequent abortive attempts that there is very little room for in the engine room! The engine has to fit below the deck in front of the lid but not foul the jet drive pully at the bottom. There is very little side to side movement available. Also it's going to be very difficult to assemble the inner cv joints so I've inserted the bearings and put the rubber gaitors over the shafts

Having previously removed the right angle gearbox for the water jet. I also had to remove the beam that held it in.

I also took the pulley off the power take off so here it is all good to go for Plan 27(a)

During the week I tried everything - putting the gearbox end in first, putting the front end in first but all to no avail. So resorted to using the tape measure and was relieved in a funny sort of way that the engine is wider that the engine bay! Not by a lot but by enough. An advantage of doing this project in a bodyshop is that nobody is shy of getting air driven saws to work. A bit of flap disk sanding as well to take a few edges off.

After a lot of pushing and shoving its in.

So that thejob done really. All I have to do now is connect the fuel pipes, the clutch, the radiator and cooing system, exhaust, air filter, drive shafts, electronics and electics, brake vacuum and everything else I've forgotten about in the year since I took the engine out!

.

No comments:

Post a Comment