After the interesting learning experience of last week it's onward with the build this week. Started off by knadgering my already dodgy knee! Good job the first thing was to buy all the bits required to repair lasts weeks damage. eBay to the rescue hopefully.

Next job was to install the handbrake cables to the lever mechanism. This was made much easier with the engine out! I knew some good would have come of it. Before the cables could be installed the yoke at the lever end had to be cut to release the cables.

Here it is pretty much assembled.

Now seems a good time to install the gear selector cables. There are two cables that translate the back and fore and the side to side movements of the lever to the gearbox. So far these are just installed from the lever to the engine room.

As the only thing so far installed that is supposed to move about, here is a short video!

A couple of other little jobs were to connect the handbrake switch...

and to bolt on the hooter...

.... little stuff but it all progresses the project!!

As the week went on the bits I needed started to arrive. The prize buy was a second hand drive shaft from a breaker. This was a complete shaft from gearbox to hub. All I need is the tripod bearing. Easy enough to pull off the rubber gaiter to expose the bearing. First thing to note is that there is about a ton of grease inside the gaiter and it will get everywhere. After that it's just a matter of releasing the circlip then pulling the bearing off the shaft. Its pretty essential before getting too rough is that you tape up around the tripod to prevent the outer bearing shells to slip off.

First plan was to pull the bearing off the shaft with a bearing puller. No luck as the jaws of the puller cant get a decent grip. Second plan was to hammer the shaft off the bearing with aa air hammer. No luck with that either. Next was to hammer the shaft through the bearing. That went quite well until the end of the shaft was flush with the bearing and it would then budge no more. Next plan was to take it to a local garage so they could push it off with a hydraulic press. No luck with that either!! Eventually a very big man with a very big air hammer was able to push the shaft out of the bearing!! Phew A big Thanks to Richard and the boys at Llanishen

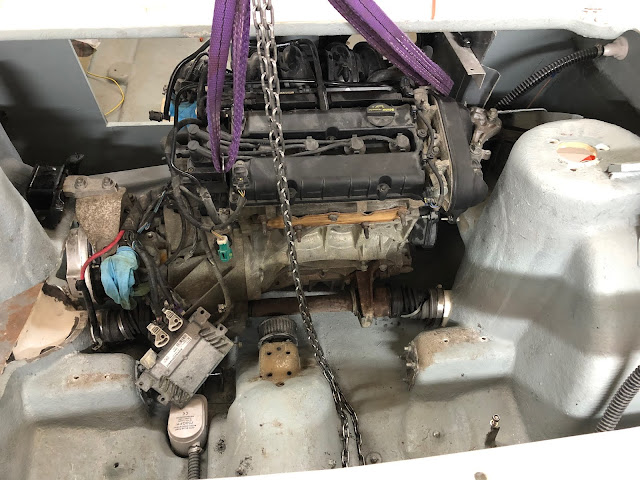

Next week its to assemble the drive shafts and get the engine back in..