It's been an interesting week at build headquarters. I left things last week with the copper plumbing pretty much in place but just needing to be clipped down. Pretty straightforward sort of a job I thought. Not so as it turned out.

The first lesson relearned was about work hardening of copper pipe. Never underestimate this! The brake pipes are 3/16", the clutch 1/4" and the fuel pipe 5/16". I'm sure that the thinner pipe work hardens less easily but the 5/16" pipes only needs a sideways glance to harden and go brittle. The brake and clutch pipes needed to start at the pedal/ABS and end at the right place in the wheel arches and engine room. The fuel pipes run from somewhere in the forepeak to somewhere in the engine room so their exact position is less critical. All the pipes have to pass through both cockpit bulkheads.

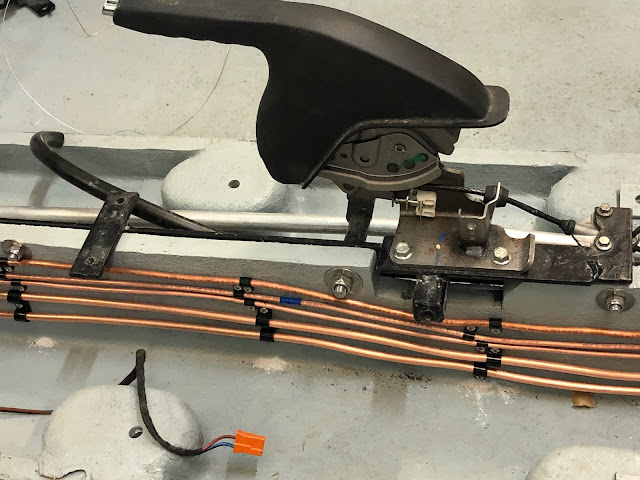

Laying out the brake and clutch pipes was easy peasy but the fuel pipes less so. In fact when it came to tidying and clipping the pipes they became so hard and brittle it became impossible and inevitably they kinked. Grr. So on to Plan B which was to buy more pipe and start again but this time in a way that involved far less manipulation of the pipe. I ran one length at a time through the forepeak straight through to the engine room then curved and clipped it from the stern forwards. So its all clipped down in the cockpit nicely now.

Here are the photos but read on to see how the week developed from here!:

So, continuing the week's story, we had quite a lot of rain on Tuesday night and on arrival at HQ on Wednesday we had this;

The gutters had overflowed into the workshop and flooded the place.

The electrical installation wasn't very happy either;

No comments:

Post a Comment